Types of Screws in PET Sheet Extruders: Single, Twin & Planetary

In the world of PET sheet extrusion, the type of screw extruder you choose can make a significant difference in production efficiency, material quality, and output consistency. PET sheet extrusion machines come equipped with various types of screws, each designed for specific applications and production capacities. In this article, we will explore the different types of screws used in PET sheet extrusion machines, including single screws, twin screws, and planetary screws, and their impact on production performance.

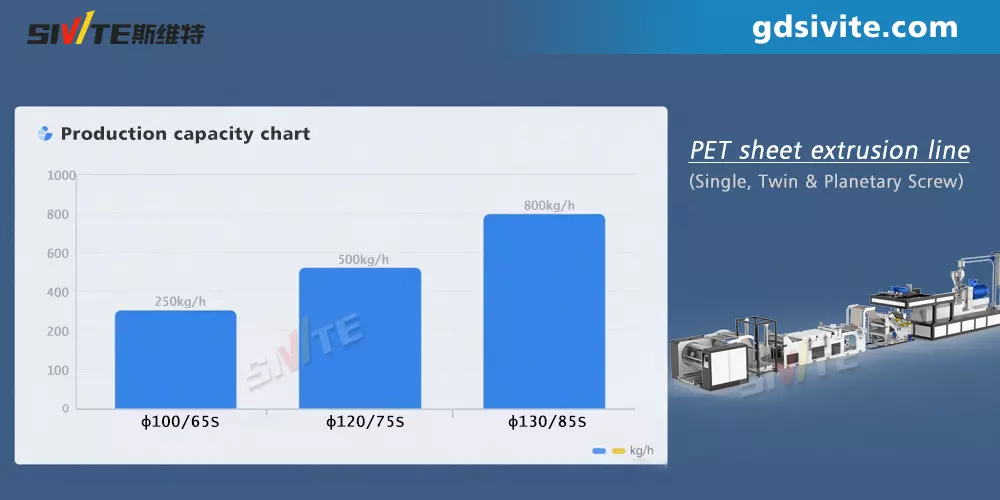

Single Screw Extruder: The Basic Choice for PET Sheet Extrusion,(More suitable for new raw materials)

Single screw extruders are the most traditional and widely used machines in the PET sheet extrusion industry. These extruders consist of a single helical screw that rotates inside a barrel, pushing the material forward while also melting and mixing it. When discussing PET sheet extrusion machines, single screw extruders are often categorized based on their output capacity.

100 Single Screw Extruder: Ideal for low to medium production volumes, the 100 single screw extruder is commonly used for smaller-scale operations where precision and versatility are required.

120 Single Screw Extruder: This size is suitable for medium-scale production and offers a good balance of cost and output.

150 Single Screw Extruder: Perfect for larger-scale PET sheet extrusion, the 150 screw extruder can handle high-volume production while ensuring high material quality.

While single screw extruders are a great option for general PET sheet extrusion, their limitations lie in their ability to handle highly viscous materials or achieve optimal mixing in certain PET applications.

Twin Screw Extruder: The High-Efficiency Option for PET Sheet Production(More suitable for recycled materials)

For higher production volumes or more complex material formulations, twin screw extruders are often the preferred choice. These machines feature two intermeshing screws that rotate in opposite directions within a barrel. The unique design of the twin screw extruder allows for better material mixing, increased output, and improved processing of complex materials such as PET.75 Twin Screw Extruder: Designed for medium to high-output PET sheet extrusion, the 75 twin screw extruder offers enhanced material mixing capabilities, improving both product consistency and performance.

85 Twin Screw Extruder: With a slightly higher capacity than the 75, the 85 twin screw extruder is perfect for high-throughput operations that demand precision and speed.

95 Twin Screw Extruder: This extruder is ideal for large-scale PET sheet extrusion operations, especially when working with complex PET formulations or multi-layer sheet structures.

Twin screw extruders are particularly well-suited for applications that require precise control over temperature, pressure, and mixing, making them a popular choice for manufacturers focused on high-quality PET products.

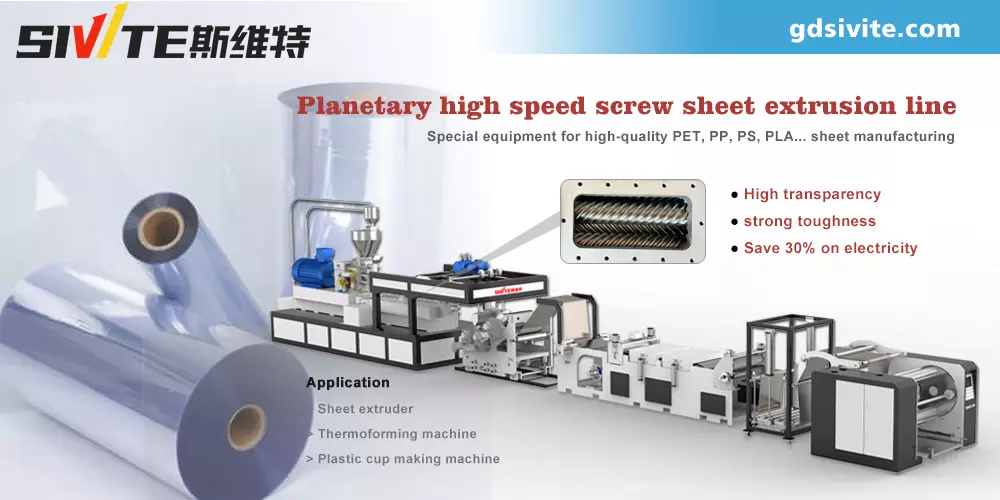

Planetary Screw Extruder: The Ultimate Solution for PET Sheet Extrusion(Suitable for any raw material)

When it comes to PET sheet extrusion machines, the planetary screw extruder is often considered the gold standard for PET processing. The planetary screw system consists of a central screw and additional planetary gears that rotate around it, ensuring maximum mixing and melting efficiency. This design is particularly beneficial when working with PET, as it allows for better material distribution, faster processing speeds, and superior output quality.

Planetary Screw Extruders for PET: These are designed specifically to meet the high demands of PET sheet production, making them an excellent choice for manufacturers who require superior performance. The planetary screw extruder excels in PET sheet extrusion because it offers:

Higher output without compromising material quality

Enhanced mixing and melting properties, crucial for PET’s high viscosity

Superior process stability, ensuring consistency across all production runs, Widely used in thermoforming machines and plastic cup making machines.

Given its superior capabilities, the planetary screw extruder is highly recommended for manufacturers focused on high-quality PET sheet production, especially when dealing with thicker or multi-layered sheets.

Choosing the right screw extruder for PET sheet production depends on several factors, including the desired output, material specifications, and production efficiency. Single screw extruders are ideal for smaller operations or simpler formulations, while twin screw extruders provide greater versatility for high-volume production. However, for those looking to maximize performance in PET sheet extrusion, the planetary screw extruder stands out as the optimal choice.