1. Single-layer PP sheet:

2. Multi-layer co-extruded PP sheet:

4. High-transparency PP sheet:

5. UV-resistant PP sheet:

6. PP non-woven sheet:

The materials used in PP sheet extrusion lines can be adjusted based on market demand, creating sheets with specific functionalities such as fire resistance, sound insulation, noise reduction, and impact resistance.

Self-developed and mastering core technologies

Diverse screw design options

The use of precision screw design (single screw, twin screw, planetary screw, multi-layer co-extrusion solutions) and intelligent control systems can achieve a stable output of 800~1500kg/h, 24-hour uninterrupted operation, reducing downtime due to material changes, and is suitable for large-volume order needs.

High-Precision Intelligent Control

It adopts self-developed intelligent AI intelligent control system, with thickness deviation ≤±0.02mm, segmented intelligent temperature control module (±1℃ accuracy), equipped with melt pressure sensor, patented hanger-type die head (adjustable width 800-1500mm), 24-hour real-time monitoring of each section's operating data, and automatic adjustment of system preset parameters.

More Energy Efficient

The highly energy-efficient, one-to-one precise temperature control heating system intelligently adjusts to avoid overheating and maintains the optimal production temperature at all times. Equipped with a full servo system and heat recovery device, it reduces energy consumption by 30%, eliminates solvent volatilization, and complies with RoHS and REACH environmental regulations.

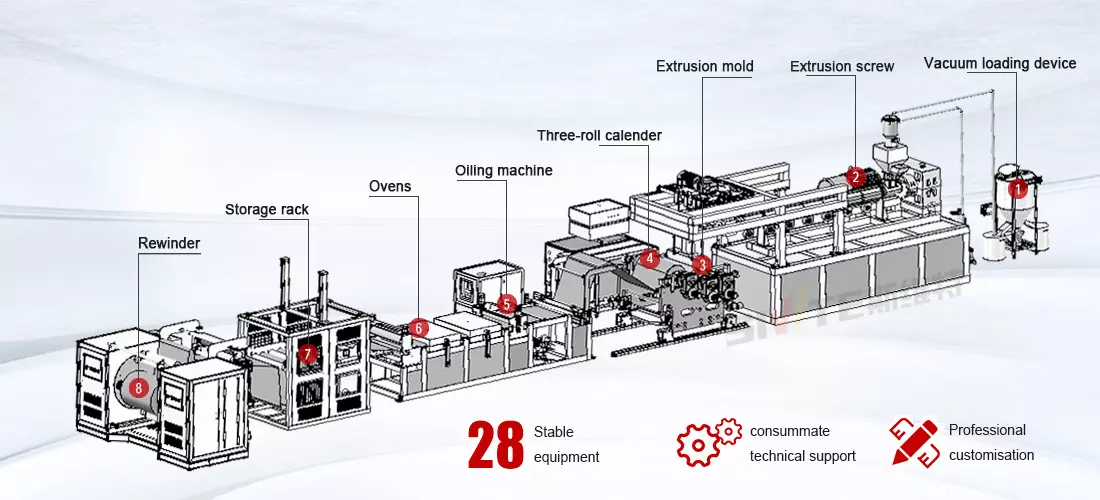

How it works (Complete sheet extrusion assembly and working principle)

A complete sheet extrusion line consists of eight key components, each of which performs a specific role while integrating seamlessly to achieve the quality requirements of sheet production.

1.Vacuum feeding system

The vacuum feeding system is a key automated feeding equipment in the PP sheet extrusion production line. It uses the vacuum negative pressure principle to achieve efficient and clean transportation of PP (polypropylene) raw materials, ensuring a continuous supply of raw materials to the machine.

2. Extrusion Screw

The core component that plasticizes raw materials through controlled heating and mechanical shear.According to the different materials produced, it can be divided into single screw, twin screw and planetary combination screw.

3. Extrusion Mold

A precision system where plasticized material first passes through a screen changer (for impurity filtration), then through a metering pump for precise volumetric control, before being distributed via flow channels to the die for final sheet formation.

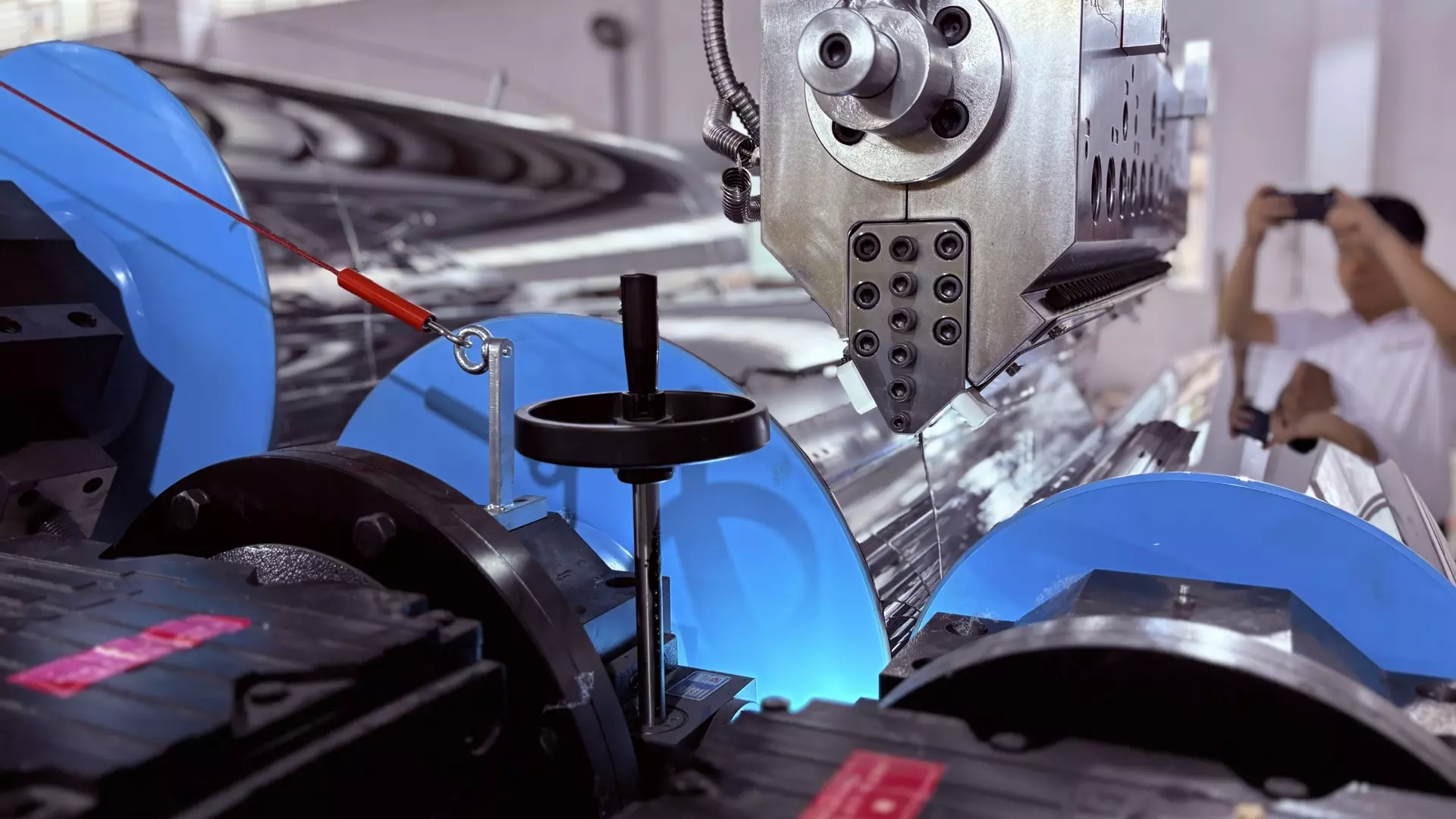

4. Three-Roll Calender

Sed ut perspiciatis unde omnis iste natus error sit voluptatem accusantium doloremque laudantium, totam rem aperiam, eaque ipsa quae ab illo inventore veritatis et quasi architecto beatae vitae.

5. Silicone Coating Unit (Optional)

Applies a release agent layer for thermoforming applications (improving mold release) or functional coatings (like anti-static treatments). Often paired with the drying oven system.

6. Multi-stage oven

Typically configured with 2-4 heating zones (depending on material requirements) to rapidly dry coated sheets before winding. Ensures proper coating curing without affecting sheet properties.

7. Accumulation Buffer

STemporarily stores sheets through adjustable web paths, preventing material damage or contamination during downstream equipment transitions or winding delays.

8. Winding Machine

Available in semi-automatic or fully automatic configurations to produce tightly wound, edge-aligned rolls. Ensures optimal material handling for storage and subsequent thermoforming processes.

This single-screw extruder conveys, melts, and homogenizes PP raw materials, then extrudes them through a flat-hanger die. This extruder offers a simple structure, low cost, and easy maintenance. It is suitable for low to medium production runs (100-500 kg/h) and general PP sheet materials (such as food packaging and stationery). While its mixing performance is average, there's significant room for improvement for highly filled or modified PP (such as flame-retardant and reinforced PP).

Co-rotating twin-screws: Provide strong shear forces and are suitable for highly filled, rPET, or modified PET (e.g., with added flame retardants or glass fiber). Counter-rotating twin-screws: Provide stable conveying and are suitable for high-viscosity PET.Twin-screw extruders use two parallel or interlocking screws to propel the material. They offer strong mixing and melting capabilities and are suitable for processing complex materials.

This equipment utilizes a combination of single and planetary screws. The rotation of the planetary screw helps improve the uniformity of material mixing. The multi-screw planetary design provides excellent mixing and plasticizing capabilities while minimizing the impact on the material's physical properties. Low extrusion temperatures reduce thermal degradation. Even with recycled materials, high-toughness sheets can be produced. This equipment is primarily used to produce high-end PP sheets.

Multi-layer coextrusion, in simple terms, consists of a multi-layer structure. Common examples include two-layer, three-layer, and five-layer coextrusion. Multiple extrusion screws are required to achieve multi-layer coextrusion. Common combinations include:

* PP/PE-HIPS three-layer symmetrical structure: skin layer (PP/PE) - middle layer (HIPS) - skin layer (PP/PE). The skin layer is a blend of polypropylene (PPa, PPb, PPc) with different melt indexes and linear low-density polyethylene (LLDPE) to enhance impact resistance, abrasion resistance, and heat resistance. The middle layer is a blend of high-impact polystyrene (HIPS) with rubber and fillers to improve flexibility and dimensional stability, mitigating warping issues caused by the difference in thermal expansion coefficients between PP and HIPS.

* PP-based asymmetric structure: Heat-resistant PP (surface layer) - functional layer (such as HDPE or LLDPE) - heat-seal layer (EVA or LDPE). Surface layer: PP offers high-temperature resistance and is suitable for retort packaging. HDPE or LLDPE enhances low-temperature impact resistance. Heat-seal layer: Ethylene vinyl acetate copolymer (EVA) improves heat-seal properties.

* Microlayer coextrusion technology (ultra-multilayer structure), alternating microlayers of PP and other polymers (such as PETG and PA) (up to thousands of layers), is primarily used in high-end electronic components, medical devices, and other applications requiring high barrier properties.

These structures are suitable for producing PP sheets requiring multiple layers or special properties, especially two-color or multi-color PP sheets, such as the popular hot pot bowls and ice cream cups, which require this multi-layer coextrusion technology.

| Model | Adaptive material | Screw structure | Specifications(mm) | Thickness(mm) | Width(mm) | Extrusion Volume(kg/h) |

| SWT-120D | PET,PLA,PP,PS,PE,PC.... | Single screw | φ120 | 0.15~2.0 | ≤1200 | 300~400 |

| SWT-130D | PET,PLA,PP,PS,PE,PC.... | φ130 | 0.15~2.0 | ≤1200 | 400~600 | |

| SWT-150D | PET,PLA,PP,PS,PE,PC.... | φ150 | 0.15~2.0 | ≤1200 | 700~1000 |

| Model | Adaptive material | Screw structure | Specifications(mm) | Thickness(mm) | Width(mm) | Extrusion Volume(kg/h) |

| SWT-75S | PET,PLA,PP,PS,PE,PC.... | Twin screw | φ75 | 0.15~1.8 | ≤1200 | 400~500 |

| SWT-85S | PET,PLA,PP,PS,PE,PC.... | φ85 | 0.15~1.8 | ≤1200 | 500~700 | |

| SWT-95S | PET,PLA,PP,PS,PE,PC.... | φ95 | 0.15~1.8 | ≤1200 | 800~1100 |

| Model | Adaptive material | Screw structure | Specifications(mm) | Thickness(mm) | Width(mm) | Extrusion Volume(kg/h) |

| SWT-120X | PET,PLA,PP,PS,PE,PC.... | Single screw + planetary screw (combination) | φ120 | 0.15~2.0 | ≤1200 | 300~400 |

| SWT-130X | PET,PLA,PP,PS,PE,PC.... | φ130 | 0.15~2.0 | ≤1200 | 500~700 | |

| SWT-150X | PET,PLA,PP,PS,PE,PC.... | φ150 | 0.15~2.0 | ≤1200 | 700~1000 |

PP multi-layer co-extrusion equipment parameters

| Model | Adaptive material | Screw structure | Specifications(mm) | Thickness(mm) | Width(mm) | Extrusion Volume(kg/h) |

| 2-layer co-extrusion | PET,PLA,PP,PS,PE,PC.... | Multi-screw (customized) | φ75+65 | 0.15~2.0 | ≤1200 | 500~600 |

| 3-layer co-extrusion | PET,PLA,PP,PS,PE,PC.... | φ75+65 | 0.15~2.0 | ≤1200 | 600~800 | |

| 5-layer co-extrusion | PET,PLA,PP,PS,PE,PC.... | φ85+65+65 | 0.15~2.0 | ≤1200 | 900~1200 |

In what fields can it be applied?

Food industry

We can produce fast food boxes, plastic bowls and plates, biscuit boxes, pastry packaging boxes, fresh food trays, and fruit fresh-keeping boxes such as strawberries, blueberries, and cherries.

Medical industry

It can produce disposable syringe packaging, Tyvek packaging boxes, medical trays, pharmaceutical blister packaging, and medical device housings such as monitors and ventilators.

electronics industry

It can produce electronic pallets, as well as outer packaging and inner pallets for electronic products such as mobile phones, tablets, smart watches, Bluetooth headsets, game controllers, etc.

Cup making industry

We can produce coffee cups, milk tea cups, drinking cups, disposable dishes, milk cups, jelly cups, ice cream cups, disposable beverage cups, etc., as well as their matching cup lids.

automotive industry

Interior parts: instrument panel, door panel, roof, seat shell; exterior parts: bumper, fender, wheel arch, roof luggage box shell; functional parts: battery module shell, motor shell, ventilation duct, etc.

Packaging industry

It can produce cosmetic linings, gift boxes, wine packaging boxes, table and chair panels, cabinet decorative layers, advertising light boxes, as well as various packaging blisters for toothbrushes, toys, etc.

Customers also asked about these related machines