Disposable Plastic Bowl Production: Injection Molding vs. Thermoforming

In the production of disposable plastic bowls, manufacturers often face a critical decision: Should they use injection molding or thermoforming machines? Both methods have their advantages, but recent advancements in plastic bowl thermoforming machines have made them a more cost-effective and efficient choice, especially for high-volume production.

This article compares injection molding and thermoforming for producing 90mm plastic bowls, focusing on production process characteristics, efficiency, and cost analysis. We will also highlight why many manufacturers are switching from injection molding to thermoforming for better profitability.

1. Production Process Characteristics

Injection Molding

Injection molding involves melting plastic pellets and injecting the molten material into a mold under high pressure. Once cooled, the plastic solidifies into the desired shape.

Key Features:

* High precision and consistency

* Suitable for complex shapes with thick walls

* Requires expensive steel molds

* Longer cycle times (typically 10-30 seconds per cycle)

Thermoforming (Using a Plastic Bowl Thermoforming Machine)

Thermoforming uses a heated plastic sheet that is vacuum-formed or pressure-formed into a mold. The SIVITE 7565 positive/negative pressure three-station thermoforming machine is an excellent example of modern thermoforming technology.

Key Features:

- Faster cycle times (1-2 seconds per mold)

- Lower mold costs (aluminum molds instead of steel)

- Ideal for thin-walled products like disposable bowls

- Easier and quicker mold changes for different product specifications

Why It Matters:

For a 90mm plastic bowl, thermoforming offers better flexibility and speed, making it ideal for businesses that frequently change product designs or sizes.

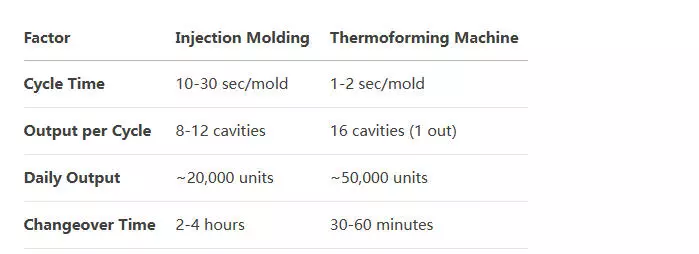

2. Production Efficiency Comparison

When comparing injection molding vs. thermoforming, efficiency is a major factor.

Injection Molding Efficiency:

- Cycle time: 10-30 seconds per mold

- Output per cycle: Typically 4-8 pieces (depending on mold design)

- High energy consumption due to heating and cooling cycles

Thermoforming Efficiency (Using SIVITE 7565 Machine):

- Cycle time: 1-2 seconds per mold

- Output per cycle: 16 pieces (one-out-of-16 mold design)

- 30% faster production compared to injection molding

Result:

A plastic bowl thermoforming machine like the SIVITE 7565 can produce up to 28,800 bowls per hour (assuming 2-second cycles), while injection molding might only achieve 7,200 bowls per hour (assuming 10-second cycles).

3. Cost Analysis: Thermoforming Saves 50% Over Injection Molding

Cost is a decisive factor for manufacturers. Here’s how thermoforming reduces expenses:

Mold Cost:

- Injection Molding: Steel molds cost $10,000-$50,000+, depending on complexity.

- Thermoforming: Aluminum molds cost $2,000-$5,000, making them 60-80% cheaper.

Production Cost:

- Injection Molding: Higher energy consumption, longer cycle times, and more labor-intensive.

- Thermoforming: Lower energy use, faster cycles, and reduced labor costs.

Total Savings:

- 50% lower production cost with thermoforming

- Faster ROI due to cheaper molds and higher output

Why Manufacturers Are Switching:

Many companies producing 90mm plastic bowls are transitioning from injection molding to thermoforming because:

1. Mold costs are significantly lower – ideal for frequent product changes.

2. Faster production means higher profits.

3. Lower operational costs improve competitiveness.

4. Flexibility: Thermoforming Allows Quick Product Changes

One of the biggest advantages of a plastic bowl thermoforming machine is flexibility.

- Injection Molding: Changing product specifications requires a new steel mold, costing thousands of dollars and weeks of lead time.

- Thermoforming: Aluminum molds are cheaper and faster to produce. Switching between different bowl sizes (e.g., 80mm, 90mm, 100mm) It only takes a few minutes.

Conclusion: Why Thermoforming is the Future of Plastic Bowl Production

For disposable plastic bowls, thermoforming machines like the SIVITE offer superior speed, cost savings, and flexibility compared to traditional injection molding.