What are the advantages of using planetary screw extruder to make PET sheet?

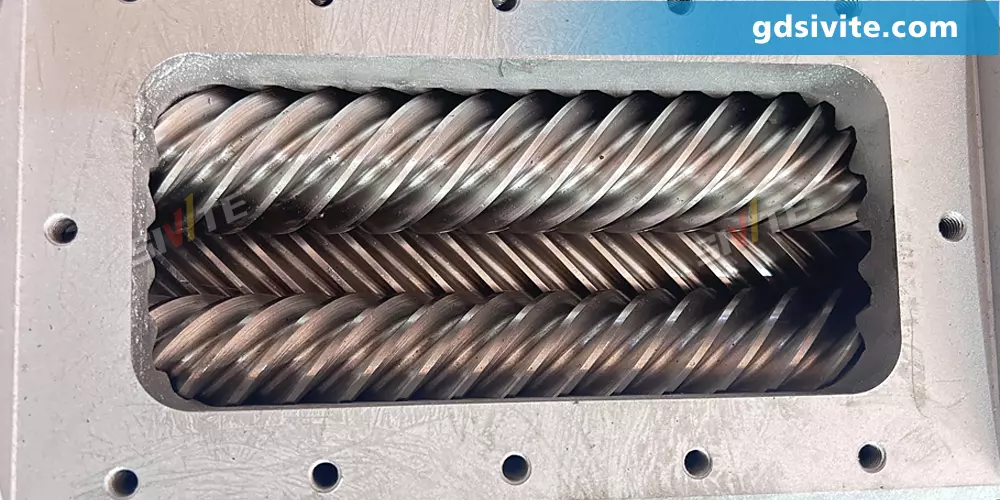

When producing high-quality PET sheets, the choice of extruder has a significant impact on product quality, efficiency and cost-effectiveness. Among the many extrusion solutions, planetary screw sheet extruders stand out for their superior efficiency and output quality. This innovative technology has many advantages over traditional single-screw or twin-screw extruders and is ideal for producing high-end PET sheets. This article will analyze the main advantages of planetary screw extruders in producing PET sheets, including sheet transparency, toughness, energy saving and other dimensions.

1. Higher Transparency in PET Sheets

One of the most significant advantages of a planetary screw sheet extruder is its ability to produce PET sheets with exceptional clarity. Traditional single-screw extruders may introduce inconsistencies in melting, leading to haze or imperfections. However, the planetary screw design ensures uniform melt mixing and better polymer homogenization, resulting in optically clear sheets. This makes it ideal for applications requiring high transparency, such as food packaging and display panels.

2. Improved Toughness and Mechanical Strength

PET sheets extruded using a planetary screw system exhibit superior toughness and impact resistance. The multi-screw configuration enhances shear distribution, reducing polymer degradation while improving molecular orientation. As a result, the sheets demonstrate higher tensile strength and durability, making them suitable for thermoforming, blister packaging, and other demanding industrial uses.

3. No Need for Crystallization & Drying – 25% Energy Savings

Unlike conventional extrusion methods, a planetary screw extruder eliminates the need for a separate crystallization and drying system for PET. The machine’s advanced screw design efficiently removes moisture during processing, reducing energy consumption by up to 25%. This not only lowers operational costs but also simplifies production, making it a more sustainable and cost-effective solution.

4. Enhanced Production Efficiency & Output Consistency

The planetary screw mechanism ensures faster melting and better polymer flow, leading to higher throughput rates with minimal material waste. Additionally, the precise temperature and pressure control minimizes thickness variations, ensuring consistent sheet quality across large production runs. Manufacturers can achieve higher yields without compromising on performance.

5. Reduced Gel Formation & Contamination

PET processing often faces challenges like gel formation and contamination, which can affect sheet quality. The planetary screw extruder’s self-cleaning action and superior mixing capability significantly reduce these issues, resulting in smoother, defect-free sheets. This is particularly beneficial for medical and high-precision packaging applications where purity is critical.

The planetary screw sheet extruder offers unmatched advantages for PET sheet production, including higher transparency, improved toughness, energy efficiency, and consistent output. PET Sheet extrusion line By adopting this advanced extrusion technology, manufacturers can enhance product quality while reducing costs—making it a smart investment for competitive plastic sheet production.