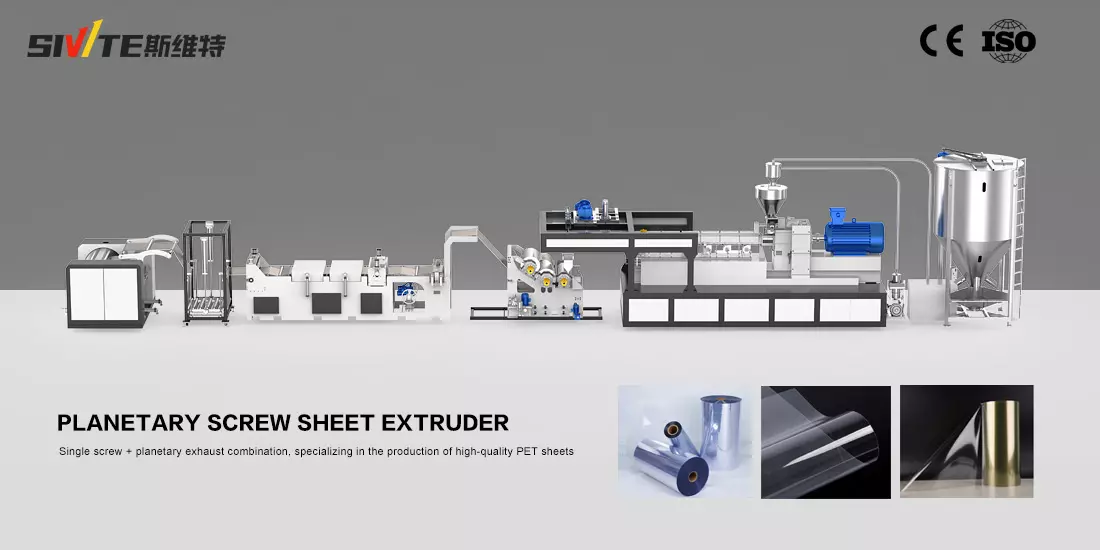

What is a planetary screw sheet extrusion line?

The PET Planetary Combination Screw Sheet Extruder is a cutting-edge solution designed to elevate the quality of PET sheet production. Featuring a unique 120 single screw + planetary screw combination structure, this extruder offers significant advantages in both performance and cost-effectiveness.Innovative Structure: Single Screw + Planetary Screw Combination

Our advanced Planetary Combination Screw Sheet Extruder features a unique 120mm single screw + planetary screw design, combining the best of both worlds. Unlike traditional single-screw extruders, this hybrid structure ensures:

1、 Superior Feeding Performance – No more feeding issues common in single-screw systems.

2、 Enhanced Mixing & Homogenization – Comparable to twin-screw extruders but with gentler processing.

3、 Minimized Molecular Damage – Preserves PET’s molecular structure for higher transparency and toughness.

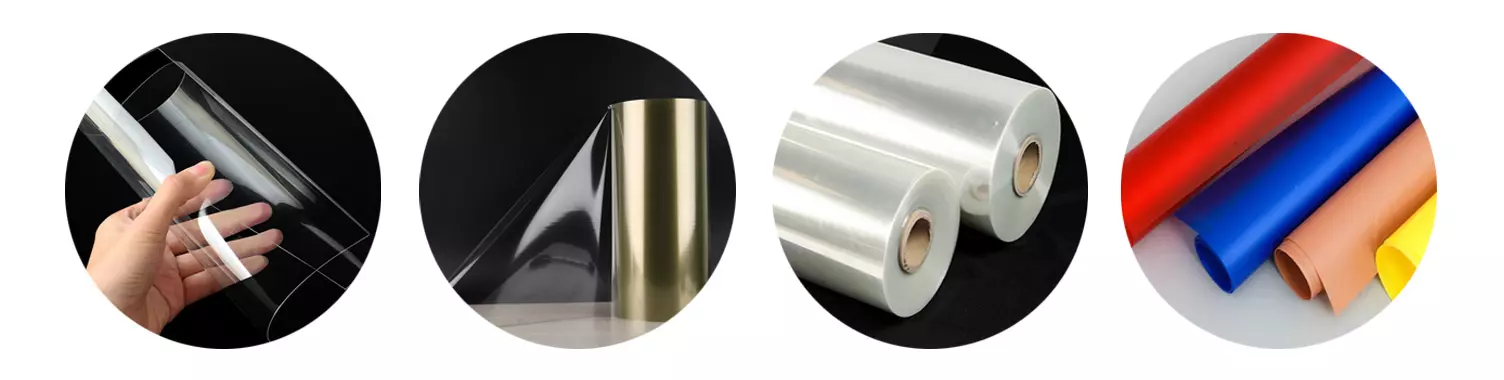

What can you do with it?

This planetary combination screw can produce higher-end plastic sheets such as PET, PP, PS, and PLA. It solves a range of sheet extrusion challenges that single-screw and twin-screw extruders currently struggle with, such as crystallization, poor toughness, and low transparency. These sheets can then be processed through thermoforming and vacuum forming machines to create a variety of plastic products, and products made with high-quality plastic sheets offer superior quality.

1. Food Packaging

Disposable plastic cups, bowls, plates, boxes, beverage cup lids, food trays, fruit and vegetable packaging trays, cake and biscuit boxes, cold drink packaging boxes, and ice cream cups.

2. Electronic Product Packaging

Blister trays (for mobile phone accessories, earphones, and electronic components), anti-static sheets and packaging boxes.

3. Daily Necessities Packaging

Cosmetic packaging boxes, medical device packaging trays, and toy packaging.

4. Industrial and Building Materials

Advertising sheets (foam sheets), file folders, stationery sheets, and engineering plastic sheets (such as those for automotive interiors).

5. Environmentally Friendly and Biodegradable Products

PLA, PBAT, and corn starch-based sheets → For making biodegradable lunch boxes, cutlery, and compostable packaging products. Planetary screw sheet extruders primarily produce food packaging sheets, household packaging sheets, electronic blister sheets, decorative building materials sheets, and biodegradable environmentally friendly sheets, which are subsequently converted into finished products through thermoforming machines or other processing techniques.

Self-developed and mastering core technologies

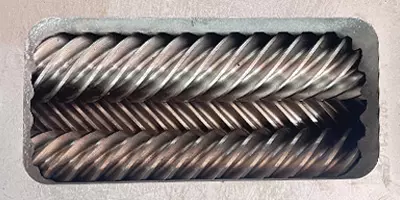

New screw structure

The combination of 120 single screw + planetary exhaust is aimed at PET, a material with good fluidity and high humidity. It not only has a good mixing effect, but also ensures the integrity of the material's molecular chain and reduces the damage to the material's original physical properties.

More energy-efficient

No crystallization drying system is required, saving at least hundreds of thousands of dollars in electricity bills each year. Unlike traditional single-screw and parallel twin-screw sheet extrusion equipment, it does not need to be equipped with crystallization drying equipment to perfectly solve the problems of PET moisture drying and degassing.

Better extrusion quality

It solves the problem of poor feeding and mixing effect of single screw, while taking into account the mixing and fast feeding characteristics of twin screw, reducing the damage to the molecular chain of the material. The PET sheet produced has many advantages such as high transparency, good toughness, and no crystal point. Choosing it for high-end sheet will take your quality to a higher level.

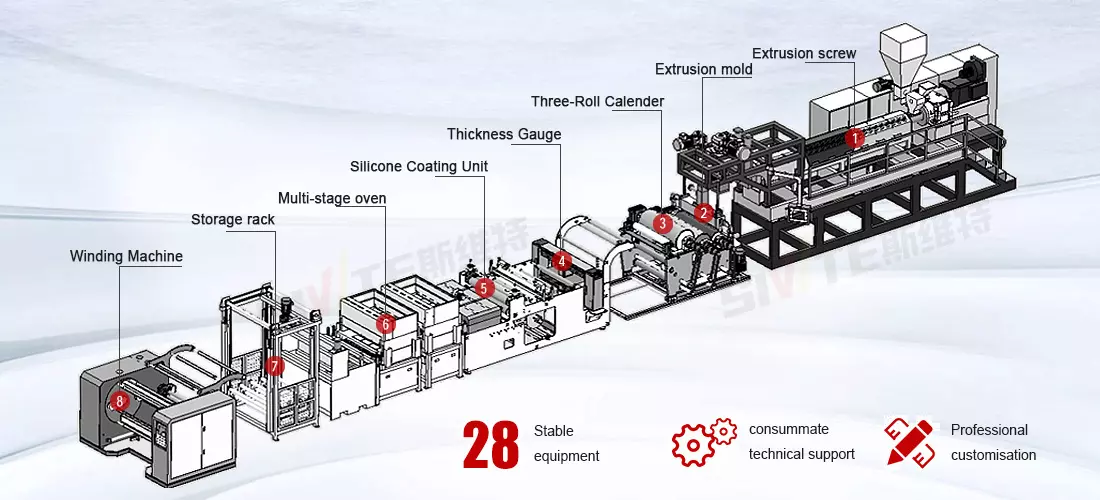

1. Extrusion Screw

The core component that plasticizes raw materials through controlled heating and mechanical shear.According to the different materials produced, it can be divided into single screw, twin screw and planetary combination screw.

2. Extrusion Mold

A precision system where plasticized material first passes through a screen changer (for impurity filtration), then through a metering pump for precise volumetric control, before being distributed via flow channels to the die for final sheet formation.

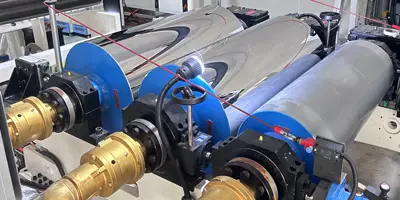

3. Three-Roll Calender

Immediately cools and shapes the extruded sheet through precisely temperature-controlled rollers, ensuring dimensional stability and surface quality.

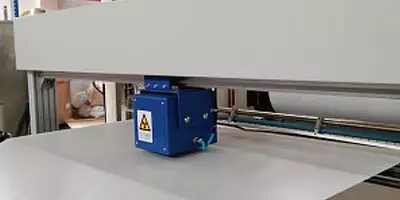

4. Thickness Gauge

Provides 24/7 real-time thickness measurement with closed-loop feedback control to maintain consistent sheet gauge throughout production.

5. Silicone Coating Unit (Optional)

Applies a release agent layer for thermoforming applications (improving mold release) or functional coatings (like anti-static treatments). Often paired with the drying oven system.

6. Multi-stage oven

Typically configured with 2-4 heating zones (depending on material requirements) to rapidly dry coated sheets before winding. Ensures proper coating curing without affecting sheet properties.

7. Accumulation Buffer

Temporarily stores sheets through adjustable web paths, preventing material damage or contamination during downstream equipment transitions or winding delays.

8. Winding Machine

Available in semi-automatic or fully automatic configurations to produce tightly wound, edge-aligned rolls. Ensures optimal material handling for storage and subsequent thermoforming processes.

| Model | Adaptive material | Screw structure | Specifications(mm) | Thickness(mm) | Width(mm) | Extrusion Volume(kg/h) |

| SWT-120X | PET,PLA,PP,PS,PE,PC.... | Single screw + planetary screw (combination) | φ120 | 0.15~2.0 | ≤1200 | 400~600 |

| SWT-130X | PET,PLA,PP,PS,PE,PC.... | φ130 | 0.15~2.0 | ≤1200 | 600~900 | |

| SWT-150X | PET,PLA,PP,PS,PE,PC.... | φ150 | 0.15~2.0 | ≤1200 | 1000~1500 |

What materials are suitable for sheet extrusion?

PET (APET, CPET, PETG):

Planetary screw sheet extrusion lines were originally designed primarily for PET, particularly APET, CPET, and PETG. These materials are widely used to produce plastic sheet for packaging, electronics, and automotive applications. PET is renowned for its excellent clarity, strength, and versatility, making it an ideal choice for high-end packaging solutions.

Polypropylene (PP)

PP is one of the most widely used thermoplastics due to its excellent chemical resistance, low cost, and ease of processing. However, PP extrusion requires high processing temperatures and pressures to ensure product uniformity and quality. Planetary screw sheet extrusion lines are optimized for these requirements, providing a stable and efficient process for producing PP sheet for a variety of applications, from packaging to automotive parts.

Polystyrene (PS)

PS is a versatile material that is easily processed into thin sheets, making it ideal for use in disposable packaging, CD cases, and other applications. Planetary screw sheet extrusion lines provide precise temperature control and material flow, ensuring the production of high-quality PS sheet with uniform thickness and clarity. This system can process PS sheets at high speeds with extremely low defect rates, making it a popular material in the packaging industry.

Polylactic Acid (PLA)

PLA is a biodegradable plastic derived from renewable resources such as corn starch or sugarcane. It is increasingly popular in the production of environmentally friendly packaging solutions. However, due to its low melting point, its processing requires strict temperature management. Planetary screw sheet extrusion lines provide precise control of the extrusion process, ensuring that the integrity and quality of the PLA sheets are maintained when processed into various products.

With the growing market demand for high-end plastic sheet, the capabilities of planetary screw sheet extrusion lines are expanding. They can now process not only PET, PP, PS, and PLA materials, but manufacturers are also continuously exploring the application of this new technology in more applications, improving and enhancing the production process for a wider range of plastic materials.

In what fields can it be applied?

Food industry

We can produce fast food boxes, plastic bowls and plates, biscuit boxes, pastry packaging boxes, fresh food trays, and fruit fresh-keeping boxes such as strawberries, blueberries, and cherries.

Medical industry

It can produce disposable syringe packaging, Tyvek packaging boxes, medical trays, pharmaceutical blister packaging, and medical device housings such as monitors and ventilators.

electronics industry

It can produce electronic pallets, as well as outer packaging and inner pallets for electronic products such as mobile phones, tablets, smart watches, Bluetooth headsets, game controllers, etc.

Cup making industry

We can produce coffee cups, milk tea cups, drinking cups, disposable dishes, milk cups, jelly cups, ice cream cups, disposable beverage cups, etc., as well as their matching cup lids.

automotive industry

Interior parts: instrument panel, door panel, roof, seat shell; exterior parts: bumper, fender, wheel arch, roof luggage box shell; functional parts: battery module shell, motor shell, ventilation duct, etc.

Packaging industry

It can produce cosmetic linings, gift boxes, wine packaging boxes, table and chair panels, cabinet decorative layers, advertising light boxes, as well as various packaging blisters for toothbrushes, toys, etc.

Customers also asked about these related machines