Sheet Extrusion Three-Roll Calender: (L-Type, Vertical, Inclined) contrast

When it comes to optimizing the production of plastic or rubber sheets, the sheet extruder is a critical piece of equipment, and the three-roll calender plays an equally vital role in ensuring high-quality output. The three-roll calender is responsible for smoothing, cooling, and thickening the extruded sheet, making it a key component in the sheet extrusion process. Understanding the different types of three-roll calenders—L-type, vertical, and inclined—is essential for selecting the right one for your production needs.

Key Functions of a Three-Roll Calender in Sheet Extrusion

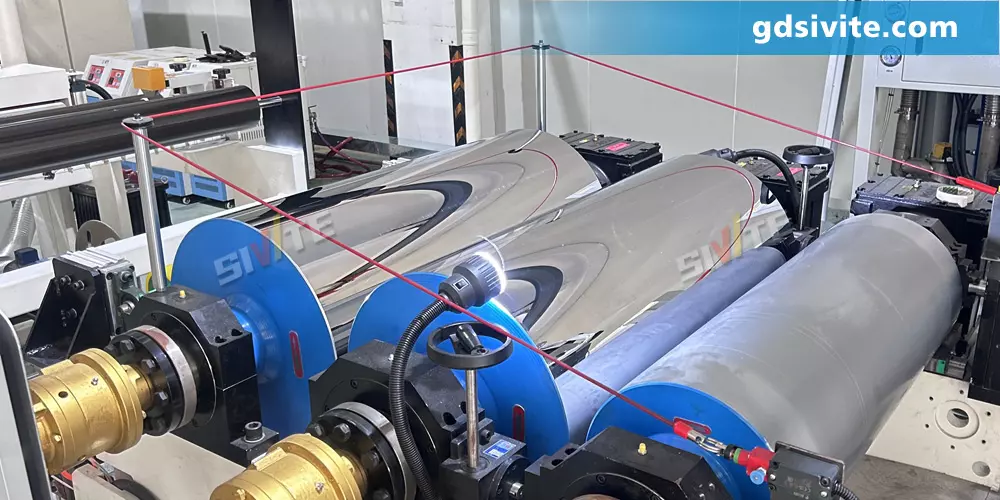

The primary role of a three-roll calender in a sheet extruder system is to flatten and cool the molten sheet as it exits the die. The rolls apply pressure to ensure uniform thickness, remove air bubbles, and achieve a smooth surface finish. Additionally, the calender helps control the sheet’s temperature, preventing warping or defects. The efficiency of this process directly impacts the final product’s quality, making the choice of calender type crucial.

Comparing L-Type, Vertical, and Inclined Three-Roll Calenders

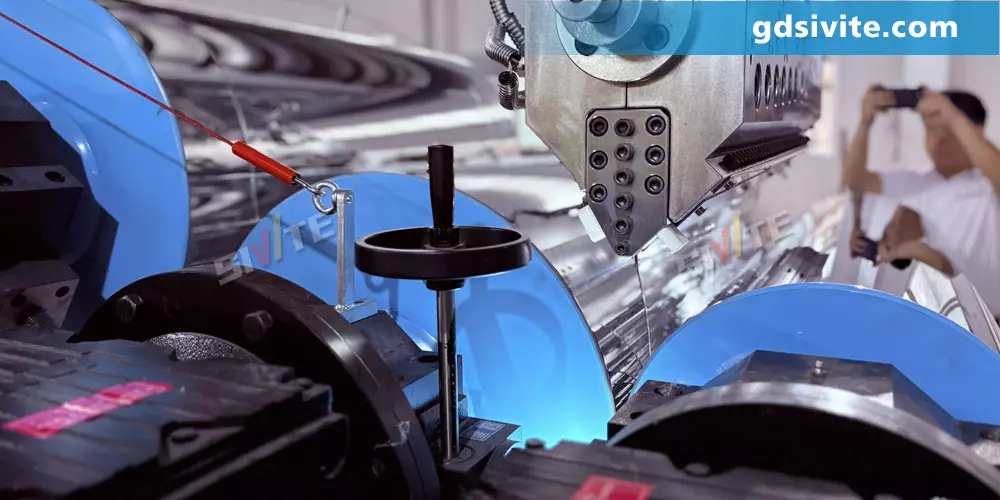

1. L-Type Three-Roll Calender: This configuration features rolls arranged in an "L" shape, with two rolls horizontal and one vertical. It is ideal for thin to medium-thickness sheets and offers excellent cooling efficiency due to the vertical roll’s direct contact with cooling systems. The L-type is commonly used in PVC sheet production.

2. Vertical Three-Roll Calender: As the name suggests, all three rolls are stacked vertically. This design provides superior pressure distribution and is often used for high-precision sheet extrusion, such as optical films or medical-grade sheets. However, it may require more floor space.

3. Inclined Three-Roll Calender: The rolls are set at an angle, combining the benefits of L-type and vertical configurations. This setup improves sheet leveling and is suitable for medium to thick sheets. It is a versatile choice for general-purpose sheet extrusion.

How to Choose the Right Three-Roll Calender for Your Needs

The selection depends on factors such as sheet thickness, material type, and production volume. For thin sheets, the L-type is efficient and space-saving. If precision is paramount, the vertical calender is the best option. For a balance of performance and versatility, the inclined calender is a reliable choice. Additionally, consider the cooling system integration and ease of maintenance when making your decision.

The sheet extruder process heavily relies on the three-roll calender’s performance, and choosing the right type—L-type, vertical, or inclined—can significantly enhance product quality and production efficiency. By understanding the unique advantages of each configuration, manufacturers can make informed decisions to meet their specific needs. Whether you prioritize speed, precision, or versatility, the right calender will ensure smooth, defect-free sheet extrusion.