PET Sheet Extrusion Line: Single Screw vs. Double Screw

When it comes to manufacturing high-quality PET sheets, choosing the right PET sheet extrusion line is crucial. Two of the most common options are single-screw and twin-screw extruders. Each type has its advantages and limitations, depending on production requirements, material properties, and cost considerations. In this article, we’ll explore the key differences between single-screw and twin-screw extruders in **PET sheet extrusion lines** to help you make an informed decision for your production needs.

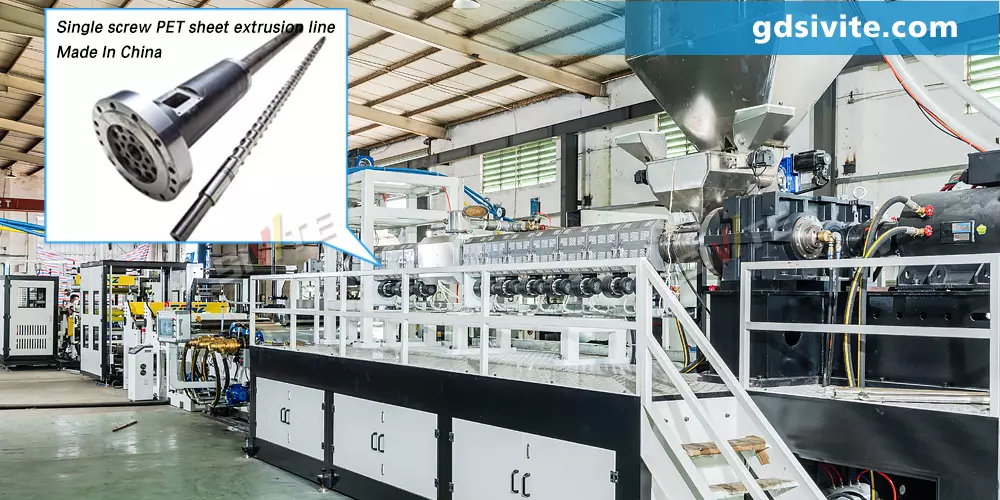

1. Understanding Single-Screw Extruders in PET Sheet Extrusion Lines

Single-screw extruders are widely used in **PET sheet extrusion lines due to their simplicity, lower cost, and ease of operation. These machines rely on a single rotating screw to melt, mix, and push the PET material through the die. They are ideal for processing uniform materials with consistent viscosity. However, single-screw extruders may struggle with mixing additives or recycled PET, as they offer limited shear and dispersive mixing capabilities. For manufacturers prioritizing cost-efficiency and straightforward processing, a single-screw PET sheet extrusion line can be a reliable choice.

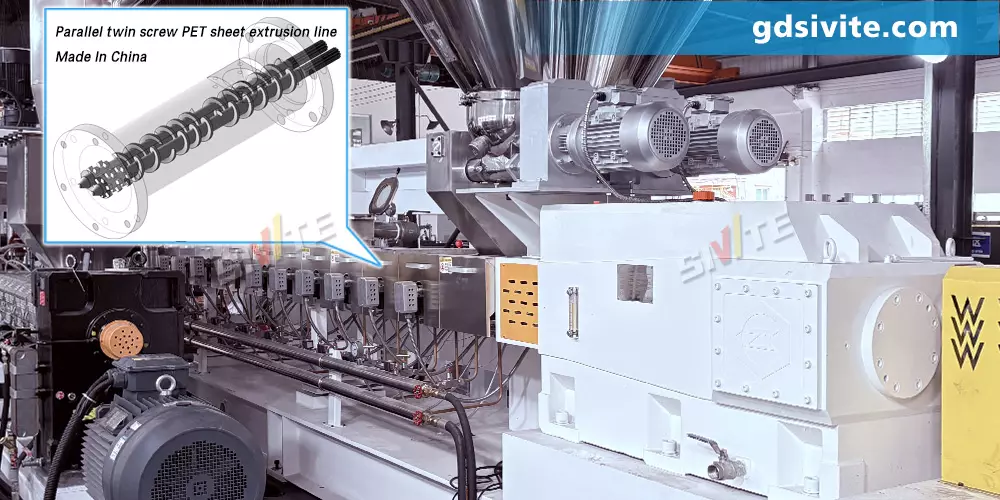

2. Advantages of Twin-Screw Extruders for PET Sheet Production

Twin-screw extruders, on the other hand, feature two intermeshing screws that provide superior mixing, better heat distribution, and enhanced material homogeneity. This makes them highly effective for processing PET with fillers, recycled content, or specialized additives. A twin-screw PET sheet extrusion line** ensures better melt quality and reduces the risk of material degradation, making it ideal for high-performance applications. While twin-screw extruders come at a higher initial cost, their efficiency and versatility often justify the investment for demanding production environments.

3. Key Factors to Consider When Choosing Between Single and Twin Screw

Selecting the right extruder for your PET sheet extrusion line depends on several factors:

>> Material Complexity – Twin-screw extruders handle mixed or recycled PET more effectively.

>> Production Volume – Single-screw extruders are more cost-effective for large-scale, simple PET sheet production.

>> Energy Efficiency – Twin-screw extruders may consume more power but offer better output consistency.

>> Maintenance & Lifespan – Single-screw machines are easier to maintain, while twin-screw extruders provide longer service life under heavy use.

4. Technological iteration of PET sheet extrusion process

As sustainability and efficiency become the primary considerations, the technology of PET sheet extrusion production lines is also constantly developing and updating. New screw designs, energy-saving features and intelligent automation are improving single-screw and twin-screw systems. And with the increasing demand for diversified materials from customers, the research and development of sheet extruders for multi-layer co-extrusion or new materials is also constantly breaking through, including whether it can be shared with other materials such as PP and PLA, which customers have always been concerned about. These will be the topics of future technological innovation.

Of course, whether you choose a single-screw or twin-screw PET sheet extrusion line, the right choice depends on your specific production needs, material requirements and budget. Single-screw extruders are easy to operate and affordable, while twin-screw systems have many advantages, such as excellent mixing performance, compatibility with raw materials and recycled materials, and high output. By evaluating these factors, you can choose the best extrusion solution to efficiently produce high-quality PET sheets.