What is a T-Type Mold Table? Why Do High-End Thermoforming Machines Use It?

In the world of industrial thermoforming, efficiency, precision, and speed are critical factors that determine productivity. One of the key components that contribute to these factors is the T-type mold table, a specialized platform used in high-end thermoforming machines. But what exactly is a T-type mold table, and why is it the preferred choice for advanced thermoforming operations? This article explores its design, benefits, and the crucial advantage of quick mold change, making it indispensable in modern manufacturing.

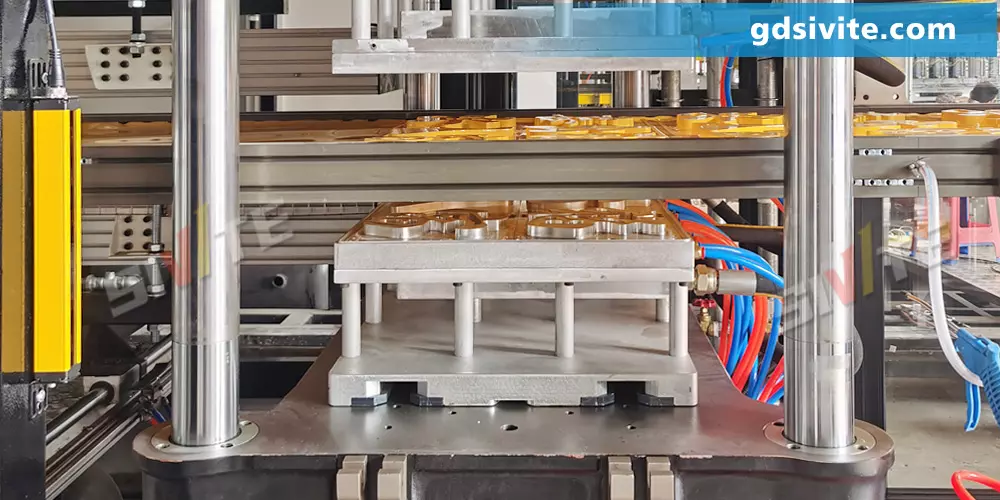

Understanding the T-Type Mold Table

T-type mold table is a robust and precisely engineered platform designed to hold molds in place during the thermoforming process. Unlike traditional flat tables, the T-shaped structure provides enhanced stability and alignment, ensuring consistent product quality. High-end thermoforming machines rely on this design because it minimizes vibration and misalignment, which are common issues in high-speed production. The "T-type mold table" is particularly beneficial for industries requiring tight tolerances, such as automotive, packaging, and medical device manufacturing.

The Core Advantage: Quick Mold Change

One of the standout features of the T-type mold table is its ability to facilitate quick mold change. In competitive manufacturing environments, reducing downtime is essential. The T-type design allows operators to swap molds rapidly without extensive recalibration, significantly improving production efficiency. Advanced clamping systems and standardized interfaces ensure that molds are securely locked in place within minutes. This feature is especially valuable for manufacturers running multiple product lines, as it enables seamless transitions between different thermoforming jobs.

Why High-End Thermoforming Machines Prefer T-Type Mold Tables

High-end thermoforming machines prioritize precision, durability, and operational efficiency—qualities that the T-type mold table delivers exceptionally well. The rigid construction minimizes deflection under high pressure, ensuring dimensional accuracy in formed parts. Additionally, the compatibility with automated systems enhances workflow integration, reducing manual intervention. Industries investing in premium thermoforming machines often opt for T-type configurations to maximize output while maintaining superior product consistency.

Applications and Industries

T-type die table function This fast die table is tailored for high-end thermoforming. From the production of complex medical packaging to automotive parts, its stability and quick change function can simplify operation. Leading manufacturers in Europe, North America and China have adopted this technology to stay ahead in the rapidly developing market. With the growing demand for high precision and high efficiency, the T-type die table will be the best design for fully automatic thermoforming machines.

The T-type die table represents a major advancement in thermoforming technology, providing unparalleled stability, precision and fast die change. More and more thermoforming machine manufacturers are adopting this technology. Whether it is a three-station thermoforming machine or a four-station thermoforming machine, this reliable and efficient mold handling solution makes it easier and faster for companies to replace and use thermoforming machine molds, saving labor and reducing costs and increasing efficiency for enterprises.