The fully automatic multi-station positive and negatve pressure thermoforming machine utilizes vacuum forming techmology for plastic sheets and features an integrated design of machinery, electricity, and pneumatics. lt is controlled by a microcomputer and PLc, with an HMl for operation.

The thre .station setup includes forming, cuting, and stacking,while the four-station setup ads hole pounching. This machine eficientiy deliers plastic shets in a single operation.

reducing labor, simplifving operation, and enhancing production efficiency, making it ideal for thermoforming and automatic punching.

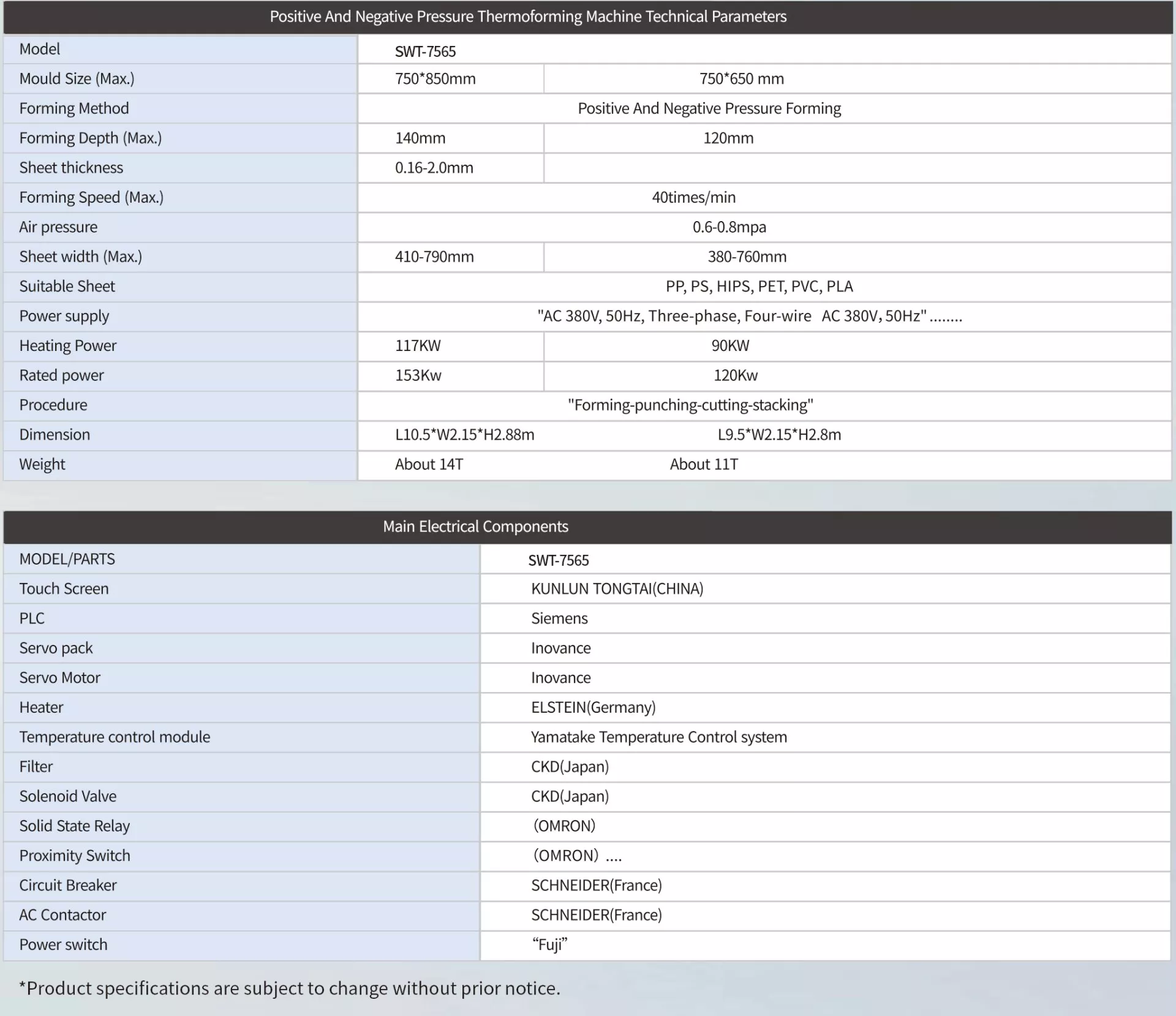

suitable for forming thermoplastic materials such asPs, HIP, PVC,PET,P,PE,PS,KPs, GPT,andAs with thicknesses ranging from 0.15 to 2.0 mm, this machine can proess hightransparency, high stretch, round,square, iregular,and bi directionaly stretched products. It can producevarious plastic productsincluding plastic lunch boxes,electronic trays,food packaging boxes, pharmaceutical packaging trays, tool packaging, seedling trays, disposable bowls, lids, and plates.